The development of infrared (fill light) technology for security cameras

Concept of light

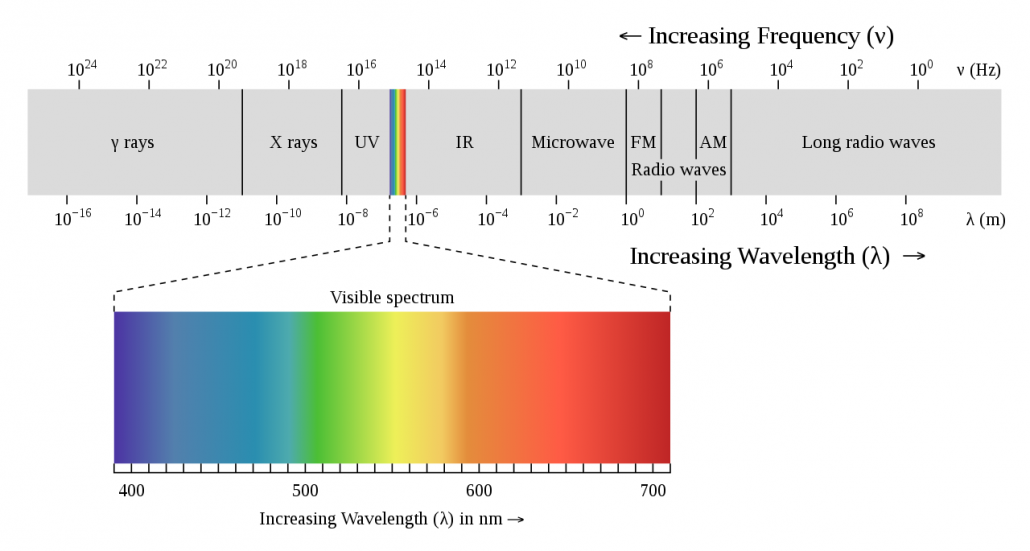

Light is an electromagnetic wave with different frequencies, and light of different frequencies will have different colors.

Human eyes can see objects because they can emit light or reflect light (the light that human eyes can perceive). But the light in nature is only part of what the human eye can perceive (see). Through research, we found that the human eye can fully see light with a wavelength between 780 and 400 nm, while the light with a wavelength between 880 and 780 nm can also be slightly perceived by the human eye. The visible light (the light that the human eye can see) is red, orange, yellow, green, blue, and indigo purple. White light is the synthesis of all these spectra.

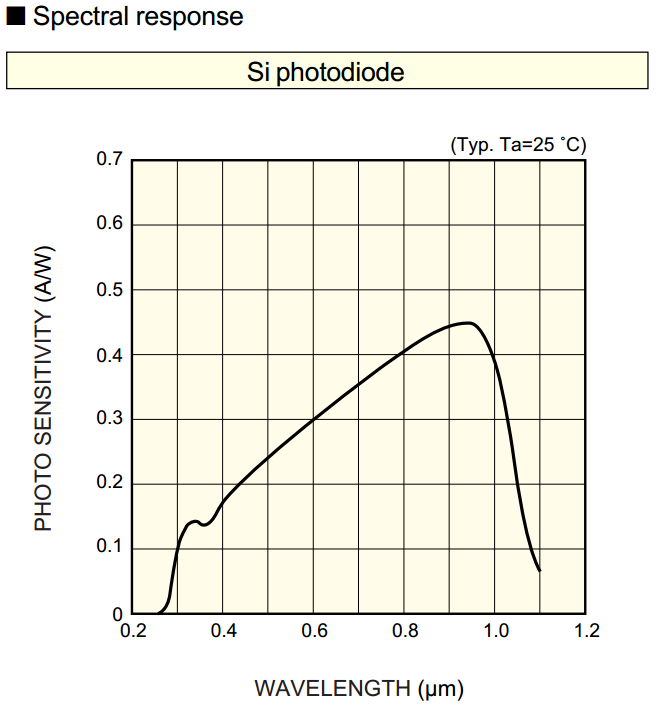

Similar to the human eye, the image sensor in the camera can also perceive light of a specific wavelength. The photosensitive element of CCD or CMOS is generally composed of silicon. The following figure shows the spectral response curve of silicon:

From the spectrum of silicon, we can see that, in addition to sensing visible light at 780-400nm, silicon is most sensitive to light at 700-1000nm. The range of 800-1000nm is infrared light. Because of this physical characteristic, CCD/CMOS cameras can better perceive infrared light, and human eyes are not sensitive to infrared light. In environments lacking visible light (such as night), security cameras often use infrared supplementary light, which will not Human eyes cause light pollution and also play a relatively concealed effect.

Infrared light

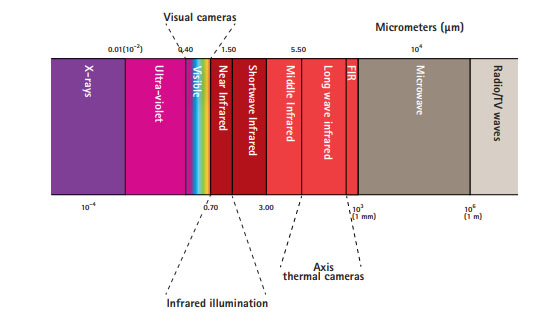

Infrared (IR) is an electromagnetic wave with a wavelength between microwave and visible light, and its wavelength is between 760nm and 1000nm.

According to different detection needs, we can subdivide the infrared light into:

- Near infrared (NIR): The wavelength range is 700 to 1000 nm (from the range that the human eye cannot detect to the range that silicon can respond to);

- Short-wave infrared (SWIR): The wavelength range is 1000 to 3000 nm (from the cut-off frequency of silicon to the cut-off frequency of the atmospheric infrared window);

- Mid-wave infrared (NWIR): The wavelength range is 3000 to 5000 nm;

- Long wave infrared (LWIR): The wavelength range is 8000 to 12000 or 7000 to 14000 nm;

- Far infrared (FIR): The wavelength range is 12000 to 30000 nm.

Near infrared (NIR) is just beside the visible section of the human eye, while medium and long-wave infrared (MWIR, LWIR) and far infrared (FIR) are farther than the visible section of the human eye.

Fill light

Infrared

In the early development of security cameras, Japanese and Korean brands such as SONY, Samsung, Panasonic, and Sharp mainly focused on the performance of cameras such as WDR and low-light. There was not much research and development on infrared technology. In the early days, SONY and Panasonic did not have infrared security cameras. The reason will be explained in detail in the section on the problem of infrared lamps. Security camera manufacturers in Taiwan and China have seen the development prospects of infrared technology in the application of security cameras, and have successively introduced infrared cameras and IR-CUT technology, which have produced very good market effects.

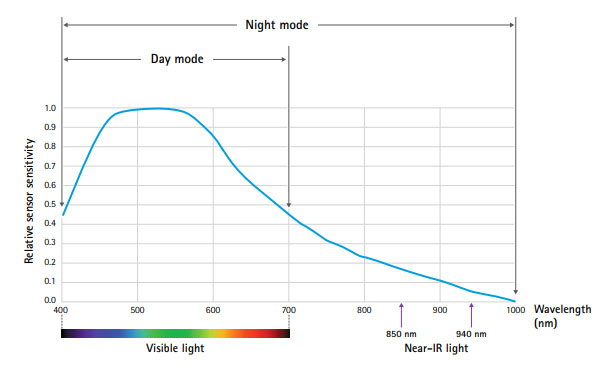

As mentioned earlier, security cameras generally use near-infrared to fill light when the visible light is insufficient. This is because the photosensitive element of CCD/CMOS is made of silicon, and silicon is very sensitive to near-infrared. At the same time, human eyes are not sensitive to near-infrared, which can avoid light pollution and be more concealed during night vision. Security cameras generally use 850nm and 940nm infrared fill light, and 850nm uses more.

As mentioned earlier, the human eye can slightly perceive the light from 880 to 780nm, so the human eye can slightly see the infrared light of 850nm (the red bright spot is visible to the human eye), while the infrared of 940nm is completely invisible, so the 940nm infrared The concealment of the camera is better. But it is a pity that the sensitivity of CCD/CMOS image sensors to 940nm light is much worse than that of 850nm. For better night vision, most infrared cameras now use 850nm infrared lamps.

The figure below shows how the CCD/CMOS image sensor responds to different light.

IR-CUT technology

In theory, objects with a temperature higher than absolute zero can emit light, all kinds of light, including visible light and near-infrared light. There are also a lot of near-infrared light in nature during the day. Although it is invisible to the naked eye, it is easy for security cameras to capture and respond to these near-infrared light. This creates a problem. Because of the interference of infrared light, the color of the color video image captured by the camera will be unreal and color cast (deviation from the color visible to the naked eye, generally purple). It is necessary to find a way to filter out the excess infrared light. . At night, in order to improve the sensitivity of the camera in a dark environment, it is necessary to absorb as much light as possible, including near infrared.

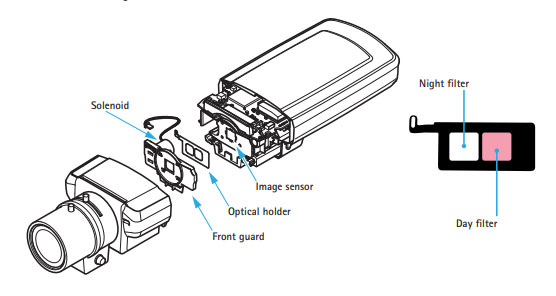

In order to meet this demand, the dual filter switching technology was produced. Dual filter switching technology, namely IR-CUT technology, the core of IR-CUT is two filters + power switching device. The two filters are an infrared cut-off or absorption filter and a full-transmission spectrum filter. IR-CUT is installed between the camera lens and the sensor. In the daytime, the default state is that the infrared cut-off filter works. The excess near-infrared passes through the lens to reach the IR-CUT, and is intercepted by the infrared cut-off filter. It cannot reach the sensor surface, thus ensuring the true color of the video image captured by the camera. In the evening, the power device on the IR-CUT is activated by light induction, the filter is automatically switched, the infrared cut-off filter is removed, and the full-transmission spectrum filter works, so as to ensure that all light (including near-infrared) can reach To the sensor, it can make full use of all the light, thus greatly improving the low-light performance of the camera. (In some cases, in order to ensure the transparency of night vision black and white images and better results, a filter that can filter visible light may be used).

Filter

The filter is made of plastic or glass with special dyes. The red filter can only let red light pass, and so on. The transmittance of the glass sheet is originally similar to that of air, and all colored light can pass through, so it is transparent, but after dyeing the color, the molecular structure changes and the refractive index also changes, which changes the passage of certain colored light.

Image sensor NIR technology

Although silicon can sensitively respond to near-infrared, in order to achieve better infrared night vision, CMOS manufacturers continue to improve the near-infrared imaging effect and sensitivity of image sensors through technology. NIR technology is the focus and core technology of image sensor manufacturers.

Infrared light development

Infrared technology is divided into passive infrared thermal imaging sensing and active infrared light emission. Security cameras generally use active infrared technology.

On the whole, the development of infrared fill light technology for security cameras has gone through 3 generations.

The first generation, traditional LED lights, in-line. A single light-emitting diode is used for packaging with epoxy resin material, and the chip size is generally between 12mil-16mil. The packaged size is generally φ5 or φ8. Condensing light is achieved through the reflective bowl in the chip and the lens on the top of the encapsulated epoxy resin. The lens can be made into different angles to match the angle of the camera lens to achieve the best effect.

Main feature:

- The single power is small. The chip size is 12-16mil, the current of a single lamp is very small, and the power is very low. In order to achieve good results, generally increase the number of particles. The number of common particles is generally 24-56, and the irradiation distance ranges from 10 meters to 40 meters. If you want to illuminate farther, it is difficult to use this LED light.

- The light decays fast. The epoxy resin lens is easy to break when exposed to heat, and the infrared light is easily refracted back through the broken surface. With the passage of time, more and more fractured surfaces, more and more infrared light is refracted back, and very little can be penetrated. This is the main reason for the fast attenuation and short life of traditional LED lights.

- Poor heat dissipation. Traditional LED lights are energized through two pins, emit light, and generate heat at the same time, and the thermoelectricity is not separated. The surrounding temperature is higher, which reduces the life of electronic components. However, if a single LED lamp is broken, it will not affect other LED lamps to continue working.

The second-generation infrared lamp is called LED Array.

Array infrared light is produced to solve the shortcomings of traditional LED infrared light. Integrate multiple low-power LEDs in a small area to provide the power of a single lamp. At the same time, a silicone encapsulation material that is not easy to break is used to reduce light attenuation and extend the life of the lamp. In addition, the thermoelectric separation process is adopted to arrange the chips on the copper substrate, and the copper substrate is connected to the camera housing to conduct heat, thereby solving the heat dissipation problem.

Then this kind of array infrared lamp was eliminated as soon as it was put on the market, and it was not recognized by the market. The main reasons are:

- The brightness is not enough. When multiple LED lights are grouped together, the overall size of the chip is too large, and there is no centralized light-emitting point. Light passes through the lens, and only a few rays can be accurately refracted to the ideal direction, most of which are reflected or refracted to other places. As a result, under the same power, the brightness of the array infrared lamp is worse than that of the traditional LED infrared lamp.

- The large number of integrated wicks leads to high costs.

Based on the advantages and disadvantages of the first and second generation infrared lamps, the third generation of infrared lamps-dot matrix infrared lamps was born. Dot matrix infrared lamps are generally referred to as IR-III. Its main features are:

- Use a single high-power LED chip, currently the most common is 42mil. The power of the third-generation dot-matrix infrared lamp is much larger than that of the first-generation LED lamp. You need to pay attention to choosing a camera power supply with a suitable current. If you use POE power supply, you need to pay attention to whether the camera can work stably after the night vision infrared light is fully turned on, whether the POE power supply, and the network transmission are normal. Sometimes the power supply cannot be guaranteed, or the POE power supply requirements cannot be met, and I would rather choose a camera that uses the first generation of ordinary LED infrared lights.

- The second generation array infrared lamp electrothermal separation technology and packaging technology are adopted. Stable work, long life, slow attenuation.

- Using secondary concentrating technology, the effective utilization rate of the light source can reach 95%. First, the reflective bowl of the wick and the lens of the encapsulated silicone form a primary condensing light, and then the reflective bowl of the lamp cup and the lens form a secondary concentrating light.

- Using a single chip, the cost is controllable.

In addition to the common 42mil chip size of the third-generation dot matrix infrared lamp, there are also 5050 (20mil), 2835 (14mil, 20mil), 3030, micro dot matrix φ5 (10mil) and other series.

The problem with infrared lights

The development of infrared fill light for security cameras has gone through many generations. Although new ones are constantly changing, the old technology products can always be retained because of the inherent defects of the infrared supplement light technology itself, and have not been completely eliminated.

- Cameras that use infrared lights have high power and heat, and are potentially dangerous when used in special industries and scenes. Such as petroleum, chemical industry, coal mine and other factories, use in workplaces, there are potential dangers and safety hazards.

- When using infrared lights, some scenes or monitored objects during night vision imaging of the camera may easily cause infrared overexposure, making it difficult to see details, such as human faces. (Of course, in view of this problem, the existing camera solution manufacturers have already targeted optimization, and the effect is very good).

- Infrared night vision is used to photograph the license plate, the license plate will reflect light and it is not clear at all. Therefore, the license plate camera generally uses white light to fill the light or does not use the fill light, and chooses a sensor solution with a better low-light ability. In the field of intelligent transportation, strobe lights or white lights are generally used.

- The infrared light will always be attenuated. After a long time of use, the night vision effect will be greatly reduced.

- The power of the infrared lamp is relatively large, and it is difficult to meet the requirements when the POE power supply or centralized power supply is used. You can only choose a camera without an infrared lamp or a camera with a lower power first-generation ordinary LED lamp.

- After the infrared lamp fills in the light, the video image is black and white. Compared with color images, details are missing, which is not conducive to finding clues, such as public security investigations. Therefore, in safe cities, the security cameras in social security generally do not use infrared, but mostly use low-light, star-level cameras.

White light (warm light)

In addition to infrared light, the camera can also use white light, warm light, and the functions are basically the same as infrared light. The difference is that white light (warm light) is used for light. Light) is essentially visible light, and its concealment is not as good as infrared light. The difference between white light and warm light is only the chromaticity and brightness of the light source.

As mentioned earlier, cameras in the intelligent transportation industry generally use white-light strobe lights or always-on lights to fill the light.

Recently, there is an infrared/white light (warm light) two-in-one dual-source fill light. Using this dual-source lamp, the infrared lamp works in general night vision scenes and has good concealment. The surveillance video image is black and white; When someone enters the monitoring area, it will trigger the camera’s humanoid detection function to alarm, thereby turning off the infrared light, turning on the white light (warm light), and the video image becomes colorful. This solves the aforementioned pain point that the night vision black and white image loses the details of the person, and the white light can also act as a warning.

The cameras mentioned above can trigger an alarm after detecting a human figure. Some manufacturers connect the cameras with warning lights or horns. When someone enters the monitoring area, it can trigger a warning light alarm or a horn voice warning. Of course, this function is not in the scope of the fill light. It belongs to the intelligent analysis and alarm function of the camera.

Photoresistor (camera auto-sensing, soft photosensitive mode)

There are two ways to turn on the fill light. One is through photoresistor, the other is through camera control.

Photoresistors are special resistors made of semiconductor materials such as cadmium sulfide or cadmium selenide, and their working principle is based on the internal photoelectric effect. The photoresistor is very sensitive to light. When there is no light, it is in a high resistance state. When the light is strong, the resistance decreases rapidly, or vice versa.

The sensitivity of the photoresistor to light is very close to the response of the human eye to visible light. As long as the human eye can feel the light, it will cause its resistance to change. This characteristic of the photoresistor can be used to control the switch of the infrared light of the camera.

When there is visible light during the day, the photoresistor senses the light, and the light board control circuit drives the IR-CUT and camera to switch to the day color mode at the same time; there is no light at night or the light becomes dim, and no light shines on the photoresistor, the light board circuit Control the infrared light to turn on, and at the same time drive the IR-CUT and the camera to switch to the night black and white mode. Therefore, after the camera is installed, the photoresistor on the light board should not be blocked, so as not to affect the normal operation of the light board.

The sensitivity of the photoresistor to light is fixed and immutable. This will cause the infrared light switch to meet our special needs in different installation environments for cameras of the same model. For example, the photoresistor is too sensitive, the visible light is still very bright, the infrared light board of the camera has started to work, and the video image has turned black; or the environment is already very dark, but the infrared light board has not been turned on, resulting in the monitoring screen being dark. can not see clearly.

In order to solve the above problems, the method of controlling the infrared light switch by sensing the light through the camera lens was born. Its core is that the camera lens captures the intensity of the light, through the camera’s internal automatic exposure and automatic white balance algorithm, control circuit, generate high and low level signals, output to the infrared light board, so as to control the turning on of the infrared light. Because there is no need for a traditional photoresistor, this method is also called soft photosensitive mode.

Compared with the traditional photoresistor control mode, the advantage of soft photoresistance is obvious: we can dynamically adjust the sensitivity of the camera’s light sensitivity as needed, thereby affecting the opening and closing of the infrared light board to meet the needs of different scenarios. On the other hand, the light sensed by the camera is dynamically changing, so that it can output a dynamically changing control signal, so that the brightness of the light board can be dynamically adjusted accordingly.

Leave a Reply

Want to join the discussion?Feel free to contribute!