Explosion-proof and anti-corrosion cameras in security

Three conditions for an explosion: ignition point, combustion-supporting gas, combustibles, none of which are indispensable. If at least one of these conditions is restricted, an explosion can be avoided.

Occasions and environments prone to explosions include oil refineries, pipeline gas transportation, oil and gas exploration, mining, etc. If you use security monitoring equipment in these places and environments, you must use explosion-proof products with explosion-proof shields. At the same time, these explosion-proof products must be appraised by a professional inspection and testing organization and meet certain explosion-proof standards. It should be noted that the explosion-proof standards are not universal in the world, and the explosion-proof standards of different countries and regions in the world are not the same.

When a potentially explosive gas-air mixture or gas-dust mixture occurs, the explosion-proof enclosure must not act as an ignition source, and ignition sparks must be avoided on the high-temperature surface of the explosion-proof enclosure. Even if there is an explosion inside, the explosion-proof enclosure can prevent sparks from leaving the interior of the enclosure.

Explosion-proof standard

GB3836

GB3836 Explosive environment The national standard specifies the protection level of electrical equipment, the classification of electrical equipment used in explosive environments, the maximum surface temperature limit, enclosure introduction devices, enclosure type tests, etc.

GB12476.1-2013 Standard for Electrical Equipment for Combustible Dust Environment

IEC 60079

Standards for electrical equipment used in explosive atmospheres formulated by the International Electrotechnical Association.

NEC500 series standards

The regional standards adopted in the United States and North America are very different from IEC 60079.

NEC505 series standard

Similarly, the standards adopted in the United States and Canada are completely equivalent and equivalent to IEC 60079 and China’s GB 3836.

EAC 51330

The Russian national standard for explosion-proof electrical equipment EAC 51330 was developed on the basis of the IEC 60079 standard.

Explosion-proof certification

FM certification

FM Approvals (FM Approvals)-the certificate to enter the global market FM Global provides testing and certification services to industrial and commercial products worldwide through its affiliated “FM Approvals” (FM Approvals) organization. The “FM Approval” certificate is universally recognized worldwide, and it shows consumers that the product or service has passed the highest standards of the United States and international testing.

ATEX 100A

On March 23, 1994, the European Commission adopted the “Equipment and Protection System for Potentially Explosive Atmospheres” (94/9/EC) directive. This directive covers mines and non-mine equipment. Unlike the previous directives, it includes mechanical equipment and electrical equipment, and extends the potentially explosive environment to dust, combustible gases, combustible vapors and mist in the air. This directive is the “new method” directive commonly referred to as ATEX 100A, that is, the current ATEX explosion-proof directive. It specifies the technical requirements to be applied to equipment intended to be used in potentially explosive environments-basic health and safety requirements and the conformity assessment procedures that must be adopted before the equipment is put on the European market within its scope of use.

IEC Ex

The abbreviation of IECEx International Electrotechnical Commission’s Explosion-proof Electrical Product Certification System, refers to electrical equipment that is specially used in industrial sectors such as petroleum, chemical, coal, textile, grain processing, and military industries where explosive gases, vapors, dust or fibers may gather explosive hazards. Certification.

EAC Ex

Russia explosion-proof certification. Russia has formulated the Russian national standard EAC 51330 for explosion-proof electrical equipment on the basis of the International Electrotechnical Commission’s IEC 60079 standard.

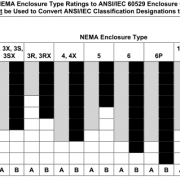

NEMA explosion-proof

American NEMA7&9 explosion-proof standard.

UL certification

UL certification was founded by the global testing and certification organization and standard development organization UL, Inc., which is mainly engaged in product safety certification.

CSA certification

Mainly applicable to the explosion-proof certification in North America.

Explosion-proof mark

A typical explosion-proof security camera is marked with Ex d ⅡC T6 Gb/Ex tD A21 IP68 T80℃, which means that this explosion-proof camera is suitable for Zone 1 and Zone 2 dangers containing explosive gas mixtures of Class ⅡA, ⅡB, and ⅡC T1~T6. Location, containing flammable dust in Zone 21 and Zone 22, and possibly at the same time hazardous places where explosive gas and combustible dust are present or separately.

Explosion-proof camera

Professional explosion-proof cameras are available from Hikvision and Axis. They are generally made of stainless steel 304 or 316L. They have passed various explosion-proof certifications. They can be used in places with explosive mixtures of flammable gas, vapor and air, and flammable Explosion hazard places formed by the mixture of natural dust and air, such as refineries, oil and gas depots, oil pipelines, substations, storage warehouses for hazardous chemicals, gas stations, etc.

Another way is to add an explosion-proof cover to the ordinary camera. The shield generally has explosion-proof certification, but the explosion-proof reliability of the camera combined in this way has not been certified, but the explosion-proof performance is generally guaranteed.

If the camera lead wire is exposed, it needs to be protected and connected to an explosion-proof junction box or equipment suitable for the use environment. Some explosion-proof cameras can be equipped with longer armored cables to ensure the explosion-proof performance of the entire camera.

Anti-corrosion standards

Anti-corrosion grade

Indoor type

- Indoor anti-medium corrosion type: F1

- Indoor anti-corrosion type: F2

Outdoor type

- Outdoor anti-corrosion type: W

- Outdoor anti-medium corrosion type: WF1

- Outdoor anti-corrosion type: WF2

NEMA4x anti-corrosion

See the article Security Camera Shell Protection Standard.

ISO12944-2

The anticorrosion international standard ISO12944-2 stipulates 6 atmospheric corrosion levels of the atmospheric environment: C1 is very low, C2 is low, C3 is medium, C4 is high, C5-1 is very high (industrial), and C5-M is very high (ocean).

Leave a Reply

Want to join the discussion?Feel free to contribute!