Security Camera Shell Protection Standard

Security camera housing involves two main aspects of protection, one is waterproof and dustproof, and the other is riot. (Of course there are special industries, such as the explosion-proof level in the petrochemical field, which will be introduced later)

Ingress Protection Rating

International Protection Marking (IEC 60529) is also known as Ingress Protection Rating or IP Code. Sometimes referred to as “waterproof grade”, “dustproof grade”, etc., it defines the degree to which mechanical and electronic equipment can provide against solid foreign objects (including body parts such as fingers, dust, grit, etc.), liquid infiltration, and accidental contact. Protection ability.

International (European) Standard

IEC 60529:2013, Code configuration

IP23CH

IP, stands for international protection

2, Prevent the entry of solid objects. Numbers 0-6 or letters

3, Prevent harmful effects caused by water ingress. Numbers 0-9 or letters

C, additional letters A, B, C, D

H, supplementary letters H, M, S, W

Detailed description of IP protection level

| First number | Meaning |

| 0 | No protection |

| 1 | Prevent solid foreign objects with a diameter of not less than 50mm |

| 2 | Prevent solid foreign objects with a diameter of not less than 12.5mm |

| 3 | Prevent solid foreign objects with a diameter of not less than 2.5mm |

| 4 | Prevent solid foreign objects with a diameter of not less than 1.0mm |

| 5 | Dustproof |

| 6 | Dusty |

| Second number | Meaning |

| 0 | No protection |

| 1 | Prevent dripping in the vertical direction |

| 2 | Prevent vertical dripping when the shell is tilted at 15° |

| 3 | Waterproof |

| 4 | Splash water |

| 5 | Water spray prevention |

| 6 | Prevent strong water spray |

| 7 | Prevent short-term flooding |

| 8 | Prevent continuous flooding |

| 9 | Prevent the influence of high temperature/high pressure water spray |

| Additional letters | Meaning |

| A | Prevent the back of the hand from approaching |

| B | Prevent fingers from approaching |

| C | Prevent tools from approaching |

| D | Prevent metal wires from approaching |

| Supplementary letters | Meaning |

| H | High voltage apparatus |

| M | Motion during water test |

| S | Stationary during water test |

| W | Weather conditions |

NEMA protection level (United States)

In the United States, the National Electrical Manufacturers Association (NEMA) defines the NEMA enclosure protection level in NEMA 250-2018.

| NEMA TYPE | Description |

| 1 | General purpose. Prevent dust, light and indirect splashing, but not dustproof; mainly prevent contact with live parts; use indoors and under normal atmospheric conditions. |

| 2 | Hourglass. Similar to Type 1, but with the addition of an anti-drip cover; it is used in places with severe condensation (such as in cooling rooms and laundry rooms). |

| 3 | Weather resistance. Prevent falling dust and dust blown by the wind, from rain, sleet and snow and other weather hazards, and not to be damaged by icing. Used outdoors in docks, construction projects, tunnels and subways. |

| 3R | Same as 3, but without protection against wind and dust. |

| 3S | Same as 3, but it can also be operated when there is ice. |

| 3X,3RX,3SX | X represents additional corrosion protection; often used near salt water. |

| 4,4X | Waterproof. Must spray at least 65 GPM of water from a 1-inch nozzle no smaller than 10 feet for 5 minutes. Used outdoors in shipyards, dairy plants, wastewater treatment plants and breweries. X (for 4X) represents additional corrosion resistance. |

| 5 | Dustproof. Provide gaskets or equivalent to remove dust; used in steel plants and cement plants. |

| 6,6P | The design of diving depends on the specified conditions of pressure and time; immersion in water or oil; used in quarries, mines and manholes. 6 can be immersed in water temporarily, 6P can withstand occasional long-term immersion. Not suitable for continuous immersion. |

| 7 | Use in areas that are certified and labeled with specific hazardous conditions: indoor use in Class I, A, B, C, and D environments defined in NFPA standards (such as NEC). |

| 8 | Use in areas that are certified and labeled with specific hazardous conditions: indoor and outdoor use in places defined as Class I, A, B, C, and D in NFPA standards such as NFPA 70. |

| 9 | Use in areas that have been certified and labeled with specific hazardous conditions: used indoors and outdoors, used in Class II, E, F or G group categories defined by NFPA standards such as NEPA. |

| 10 | Meet the requirements of 30 CFR Part 18 (1978) of Mine Safety and Health Administration. |

| 11 | General purpose. Prevent the corrosive effect of liquid and gas. Meets dripping and corrosion resistance tests. |

| 12,12K | General purpose. Designed to be used indoors to prevent dust, falling dust and dripping non-corrosive liquids. Meets dripping, dust and rust resistance tests. |

| 13 | General purpose. Mainly used to provide protection against dust, water spray and non-corrosive coolant. Comply with oil drainage and anti-rust design test. |

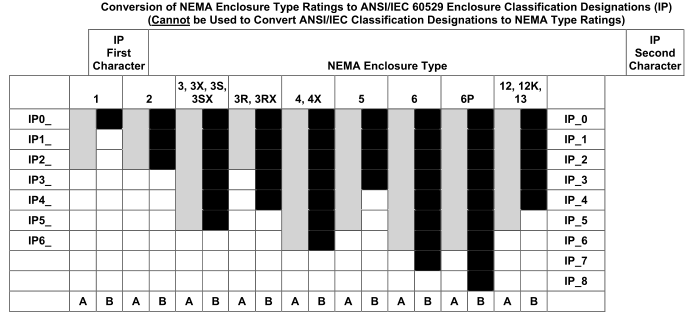

The following two tables compare the link between the NEMA 250-2018 standard and the IEC 60529 IP code. It should be noted that the values between these two standards are not completely equal: NEMA standard values and other product characteristics and tests that are not covered by the IEC 60529 standard (such as functions under icing conditions, enclosures in hazardous areas, cable connections Beating etc.).

| NEMA | IP protection standard |

| 1 | IP20 |

| 2 | IP22 |

| 3,3X,3S,3SX | IP55 |

| 3R,3RX | IP24 |

| 4,4X | IP66,IP65 |

| 5 | IP53 |

| 6 | IP67 |

| 6P | IP68 |

| 12,12K,13 | IP54 |

UL50 standard

The UL50 standard is a standard for electrical equipment enclosure requirements. Standard for safety: Enclosures for Electrical Equipment, Non- Environmental Considerations.

The core content is to further explain the content of the NEMA 250 standard, perfect and play. UL is a commercial company, so the UL50 standard is a commercial certification standard. The specific content can be viewed in the text of the UL50 standard, which will not be described in detail here.

Japanese Industrial Standard JIS Waterproof Rating (IPX)

JIS is Japanese Industrial Standards, Japanese Industrial Standards. JIS has formulated a special enclosure protection level, namely JIS C 0920:2003, which is basically the same as IEC 60529. The waterproof protection is divided into 10 levels from 0-9, which are represented by IPX1, IPX2…

| IPX | Meaning |

| IP0 | No protection |

| IP1 | Water droplets falling vertically have no harmful effects |

| IP2 | Water droplets falling within 15° of the vertical have no harmful effects |

| IP3 | Rainfall within 60° of the vertical has no harmful effects |

| IP4 | No harmful effects from splashing water in any direction |

| IP5 | Directly affected by water jets in any direction without harmful effects |

| IP6 | Directly sprayed by water in any direction will not enter the interior |

| IP7 | Do not enter the interior even if immersed in water under specified conditions |

| IP8 | It can be used even if it is immersed in a certain pressure of water for a long time |

| IP9 | It can still be used in humidity with a relative humidity of more than 90% |

IK protection level

GB/T 20138-2006/IEC 62262:2002, IK code used to describe the protection capability of enclosures against mechanical impact.

| CODE | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK10 |

| Joule | 0.14 | 0.2 | 0.35 | 0.5 | 0.7 | 1 | 2 | 5 | 10 | 20 |

Impact energy, joules. 1 joule (J)=0.102kg·1m (kg·m), which is equivalent to the energy of moving a 0.1kg object forward by 1 meter.

Leave a Reply

Want to join the discussion?Feel free to contribute!